The diagram shows the development of a production process.

Yoghurt

White Cheese

Kashkaval

-Pasteurizing the milk to a temperature of 85 ° C. (T1)

-Cooling the milk down to – 45 ° C. (T2)

-Add the starter from the dispenser 1 and mix.

-Time for the starter to be activated- 10 minutes (t1)

MILKER processes are finished

The total duration of the process- 3 hours..

After the process is finished, further germination and packaging is about 3h.

The diagram shows the development of a yoghurt production process.

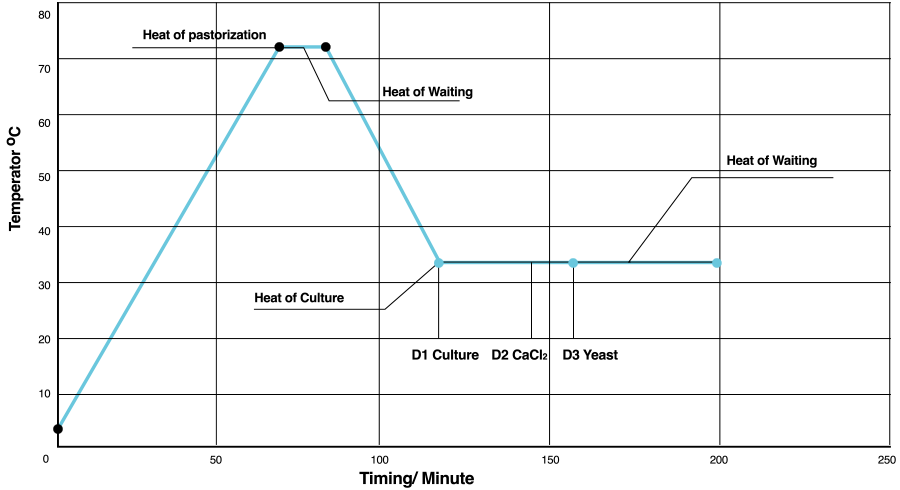

-Thermization of milk up to (T1) –72 celsius,retention-15 min.

-Cooling the milk to (T2) -34 ° celsius

-Adding starter bacteria (dispenser D1) stir and wait (t1)for

the starter activation -7 minutes

-Addition of calcium dichloride (dispenser D2), stirring

-Adding rennet yeast (dispenser D3), stirring

-Resting (coagulation time) – (t 2) – 50 minutes

-Cutting

-Resting

-Stirring

-Resting

-Cutting

-Stirring

(4-step cutting)

MILKER processes are finished

Total process time 3.5-4 hours.

After the process has been completed-press, salt and put in additions, according to your recipe.

The diagram shows the development of a white cheese production process.

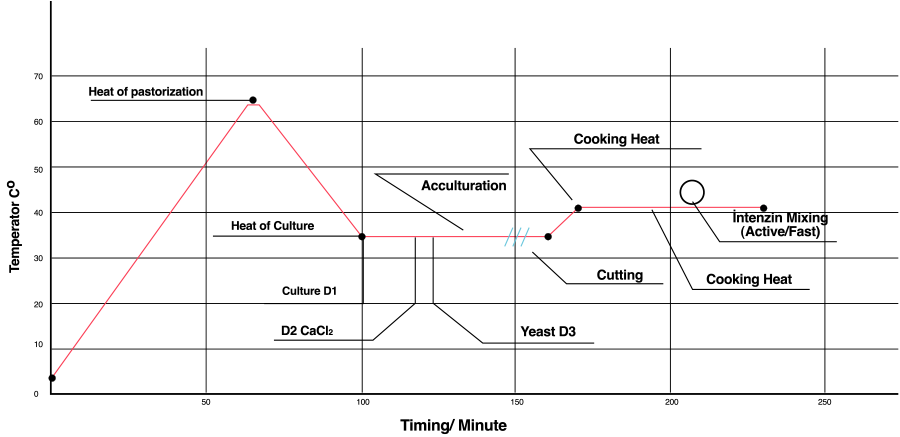

-Termination of milk to (T1) – 64 degrees, celsius,

-Cooling of the milk to (T2) – 34 degrees celsius

-Adding the bacterial starter from (dispenser D1), stirring.

-Calcium dichloride is added via (dispenser D2), stirring.

-Activation time for starter – (t1) 15 min.

-Adding the rennet yeast (dispenser D3), stirring.

-Resting (coagulation) – (t2) 45 minutes.

-Cutting – at 7 degrees

-Heating at (T3) 42 degrees Celsius

-Duration of the heating process (t3) of 60 minutes with continuous stirring.

MILKER processes are finished.

Total process time 4.5-5 hours.

After the process has been completed-press, salt and put in additions, according to your recipe.

The diagram shows the development of a kashkaval production process.