MILKER 600

The MILKER milk processing robot is designed to automatically carry out the thermal, mechanical and biochemical processes needed in the production of various dairy products.

MILKER is a mini dairy robot for automated processing of milk in various long-life dairy products.

Storage

Pasteurisation

Yoghurt and Cheese making

Heating

MILKER Machines

Yoghurt and other boutique yoghurt products.

Soft Cheese;

Mozzarella, white cheese, and other boutique soft cheeses.

Hard Cheese;

Kaşkaval, Emmental, Gouda, Edam and other boutique hard cheeses.

can produce perfectly

MILKER Machines,

Ease of production and

provide to saving…!

Extremely easy to operate and clean

Designed for small and medium farms

With minimal energy consumption

Тechnical İnformation

Installed Power

29 kW

29 kW

Weight

300 Kg

300 Kg

Energy consumption per cycle

70 kWh

70 kWh

Dimensions

2700x1750x1600 (mm)

2700x1750x1600 (mm)

Storage

4°C degrees up to 36 hours

4°C degrees up to 36 hours

A schematic diagram of MILKER.

- Heat pump unit, providing the most efficient way for the required temperatures of the various processes, including storage and pasteurization 10 kW cooling power 12 kW of heat output 4 kW electric power.

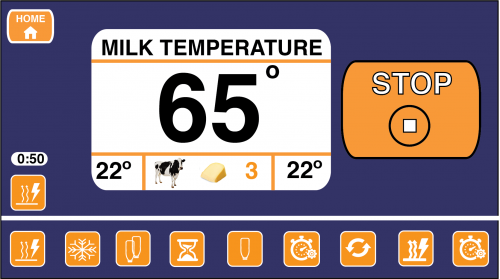

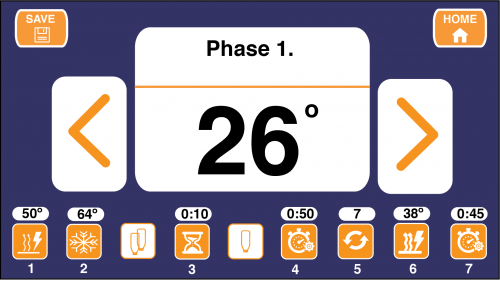

- Control panel with a touch-sensitive display for the input of user-defined functions;

- Bacterial yeast and enzyme dispensers

- Shaft control and mixer drive mechanism;

- Tank with a useful volume of 600 liters with heaters -30 kW .

- Drainage tap for the finished product

- Fan with a heat exchanger

Touch screen

Control Board